Toilet Paper Production Line From Bamboo to Toilet Paper Rolls

Bamboo Toilet Paper Making Machine is complete Toilet Paper Production Line From Bamboo to Toilet Paper Rolls

Bamboo Toilet Paper Making Machine

This machine could make toilet paper ,napkin paper etc from bamboo.

1)100% chemical pulp machine from bamboo.

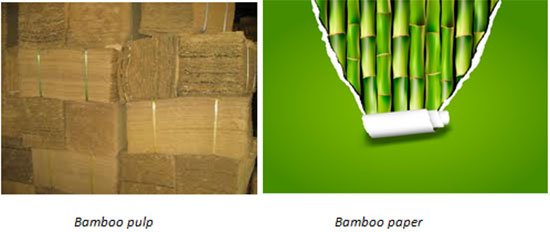

Bamboo pulp is a type of paper pulp. It is made from bamboo, nanzhu, cizhu and other bamboo materials, and is usually prepared by the sulfate method and the caustic soda method. There are also de-greening of tender bamboos and pickling with lime to make semi-clinker. Fiber morphology and length, intermediate between wood and grass fibers. Easy to sizing, bamboo pulp is medium fiber length pulp, fine and soft. Pulp tensile bulk, high tear, low burst strength and tensile strength. have high mechanical strength

Bamboo pulping mostly adopts sulfate method or caustic soda method to produce chemical pulp (see chemical pulping), with a yield of about 50% and high mechanical strength. Bamboo pulp tends to turn yellow after bleaching, and multi-stage bleaching can suppress the tendency of yellowing. Bamboo pulp fiber is slender, high in hemicellulose content, easy to swell when beating, difficult to cut, and easy to apply glue. The copied paper is compact, tough and water-resistant, but brittle and has low opacity.

2.How to make bamboo paper ?

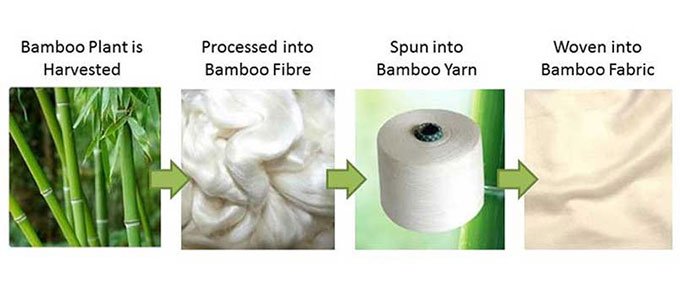

Material preparation: choose mature bamboo and cut it

Making Bamboo Chips with a Bamboo Cutting Machine

Bamboo chips are washed and desanded

The washed bamboo chips are conveyed to the cooking pot by the belt

Cooking: After the bamboo slices are installed, add the cooking liquid into the cooking pot. After the cooking liquid is added, the cooking liquid is circulated and heated to cook the bamboo slices.

Screening: pump the cooked slurry to the pressure deknot machine for rough screening Washing: use washing equipment to wash and purify the slurry: pump the cleaned slurry to the slag removal system for slag removal

Paper making: Pump the qualified pulp to the papermaking workshop, and carry out papermaking according to the process of pulping, batching, and papermaking. The paper produced is bamboo pulp paper.

Processing: Send the qualified bamboo pulp paper base paper to the post-processing workshop for household paper processing. Packaging: Pack the produced bamboo pulp paper for cleaning and convenient transportation.

2)parent tissue paper making machine

Paper machine is a general term for a complete set of equipment that makes pulp into paper webs, including headbox, wire section, press section, drying section, calender, reel and transmission section. , vacuum, lubrication, heat recovery and other auxiliary systems.

It is a machine that converts the pulp water suspension that meets the requirements of papermaking into paper through the processes of filter dehydration, mechanical extrusion dehydration and drying. The paper machine includes 3 main parts of forming, pressing and drying to complete the above process, and is equipped with necessary finishing, coiling and transmission devices, as well as pulp supply, pulp and white water circulation, vacuum, ventilation and exhaust, damage Paper handling and lubrication, automatic control and other auxiliary systems. The specifications of the paper machine are often expressed by the width of the finished paper (referred to as the width of the paper), the width of the copper wire and the preferred working speed. Modern large-scale paper machines can reach 11m in width, work at a speed of more than 1000m/min, and produce hundreds of tons of paper per day. In general developing countries and the production of some special papers, small paper machines are mostly used, with a width of 1 to 3 meters and a working speed of tens of meters to 200 meters per minute.

If you have any needs , please fill out the form below and we will contact you as soon as possible.